HMPD9000 Series

Hot Material Position Detector

HMPD9000 Series Lineups

| Model | Type | Power supply | Detection method | Download |

|---|---|---|---|---|

|

HMPD9000 |

Water-cooled | 24VDC | CCD scanning | |

|

HMPD9001 |

Water-cooled | 24VDC | CCD scanning |

Feature

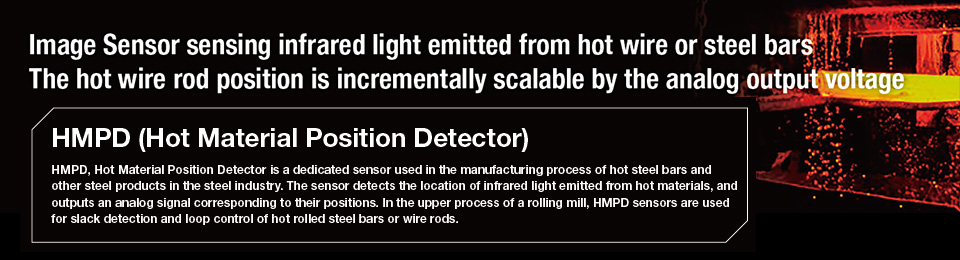

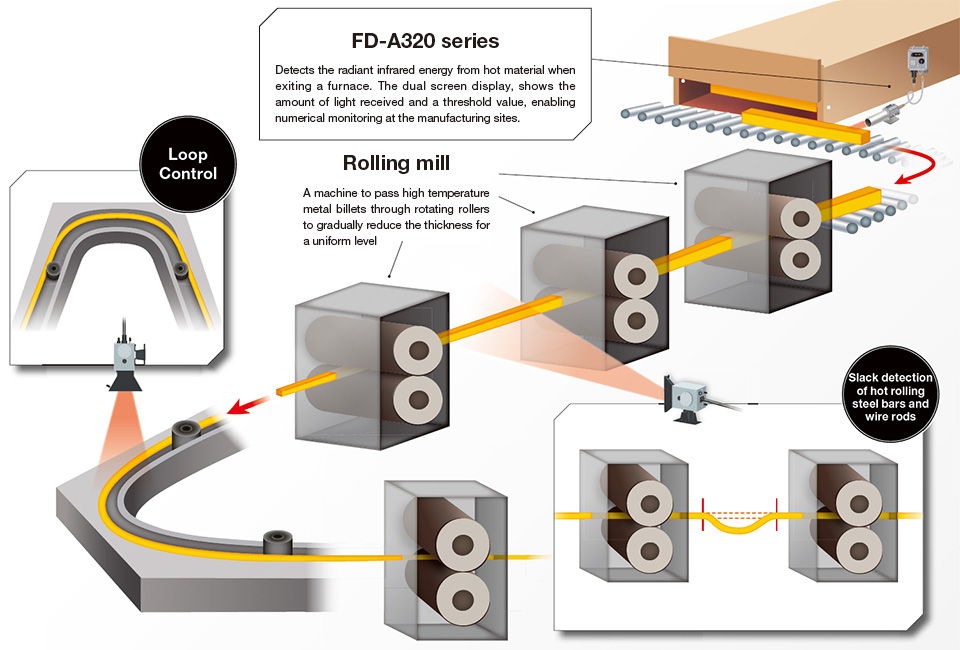

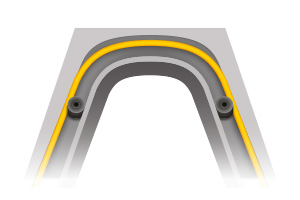

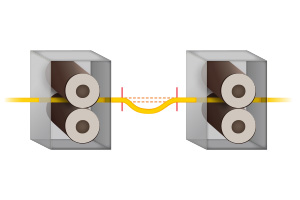

Best Suitable for Slack Detection and Loop Control of Hot Rolled Steel Bars / Wire Rods

HMPD9000 / 9001

Redesigned from the prior HMPD801-EX model but with more advanced technology, HMPD9000/9001 has improved detection performance without compromising its compatibility specifications. This enables detection of hot materials at a wider range of temperatures, now down to 680 ºC which the prior model could not detect.

Optimized optical system and electronics further clearly capture the bounding edges of hot materials, which also contributes to an improved accuracy in the actual position information of the bar materials and a faster response time, realizing even better loop control precision.

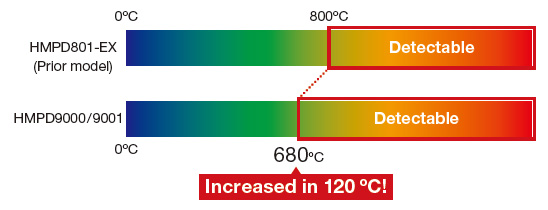

Improved Detection Capability

Detectable minimum temperature: 680 ºC

Approximately 18% increase in the detection range compared to our prior model (specified at 800ºC), meaning installation is now practical as part of downstream processes in which temperatures are lower.

Backward Compatible with our Prior Model

Compatibility assured; the prior model HMPD801-EX can be updated via a simple process.

Conforms to EU Directives

CE certificated, in response to user requests

Easy Maintenance

Easy maintenance, as there are no mechanical systems which require periodical replacement/inspection

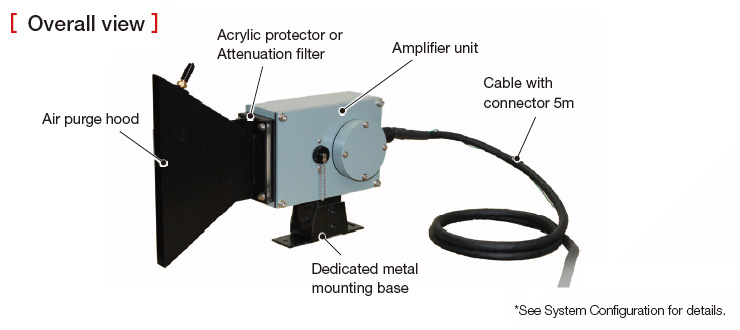

System Configuration

Dimension

HMPD9000

HMPD9001 (Units: mm)

Typical combination of air purge hood and dedicated metal mounting base (Units: mm)

Cable with connector 5m (PD801-H5) (Units: mm)

Circuit

Connection

Connector the PD801-H5 cable (5m in length,sold separately) to the sensor body.

The dedicated connector cable (PD801-H5) must be installed in a separate conduit (duct).

Install DC power source in a location within reach of the connector cable (5m). Do not extend the power cable.

To extend the input/output wire, use shielded twisted pair wire of at least 0.5mm² cross-sectional area and a terminal block for connection. The maximum extension distance is 500m.

Input / Output Circuit

Steel/Ceramic

Loop Control

Loop position is detected by controlling the speed

Steel/Ceramic

Slack detection of hot rolling steel bars and wire rods

The roller speed is controlled by detecting slack

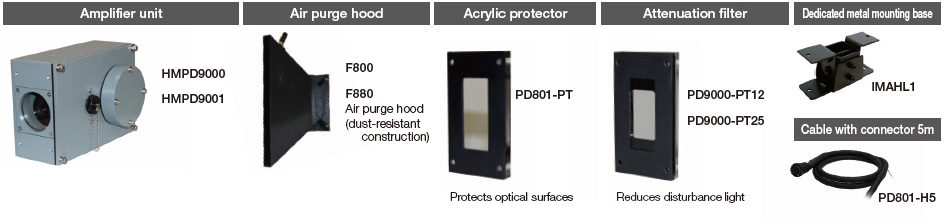

Option

Hood

| F800 |

|

||

| F880 |

|

Protector

| PD801-PT |

|

Attachments

| PD9000-PT12 |

|

||||

| PD9000-PT25 |

|

Mounting bracket

| IMAHL1 |

|

Cable with connector

| PD801-H5 |

|