Sample Applications

- Semiconductor

- Electronic Component Mounting

- Automatic assembly

- Consumer electronics/OA

- Metal processing

- Steel/Ceramic

- Delivery/Transportation

- Logistics

- Automobile

- Textile

- Rubber/Plastic

- Printing

- Packaging/Food/Drug

- Safety

- Sanitary/Amusement

- etc.

Automatic assembly

Detection of exhausted parts in parts feeder

Parts assumed to have run out when a certain level of light continuously detected for a certain period of time by retroreflective sensor.

Checking for the presence of caps

Presence of caps on works checked by retroreflective fiber optic cable.

Outer diameter inspection

Wide area fiber optic cable used in combination with two-output amplifier for diameter inspection.

Weld joint detection

Joint of motor body detected before welding. Variable focus reflective laser sensor allowing optimized adjustment according to distance.

Checking for upside-down parts

The side of parts facing up determined by level of reflected light.

Checking of parts assembly

The convergent reflective sensor detects objects to be assembled into small parts.

Position control of stick-on tape

Analog output fiber optic sensor used for detecting edge of tape for prevention of displacement of tape.

Checking the shape of coated object

Height of coated object determined by separate outputs for light axes.

Detection of oil level

Ultrasonic sensor measures the distance to the oil surface without contact.

Detection of level of material inside hopper

Detection of level of material inside hopper

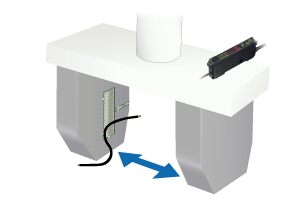

Work detection

Detection of workpiece at the chute section of parts feeders.

The detection status is presented on the dual display of the fiber optic sensor.

Classifying objects by length

Several sensors are used to identify the length of carton boxes.

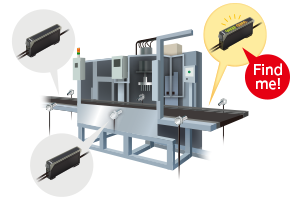

Identify a specific sensor

The location indicator activates the sensor display flashing and pinpoints a specific sensor as needed.

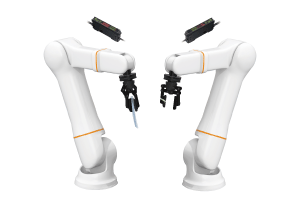

Gripping confirmation by robot hands

Preventing interference with other photo sensors

Confirmation of gripping cable or tube

Detect object reliably passing through unfixed position